客户案例

Full-automatic bagging machine for large pills

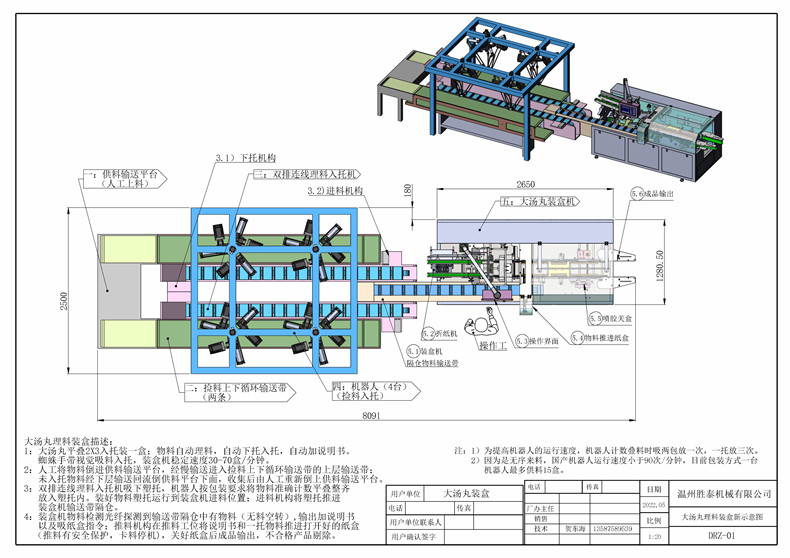

Overview of large pill automatic packing machine:

1. The large pill is folded flat 2X3 into a box; The material is automatically processed, automatically lowered into the tray, and automatically added with instructions. The spider carries the visual suction material into the tray, and the cartoning machine has a stable speed of 30-70 boxes/minute.

2. The material is manually poured into the feeding conveyor platform, and then slowly conveyed into the upper conveyor belt of the picking up upper and lower circulation conveyor belt. The materials that have not been placed in the tray will be transported back to the bottom of the feeding platform through the lower layer, and then will be manually poured back to the feeding and conveying platform after being collected.

3. The double-row line material handling machine absorbs the plastic tray, and the robot accurately counts the materials and neatly folds them into the plastic tray according to the packaging requirements. The plastic tray of the loaded material runs to the feeding position of the cartoner, and the feeding mechanism pushes the plastic tray into the bin of the conveyor belt of the cartoner.

4. The material detection optical fiber of the cartoning machine detects that there is material in the conveyor belt compartment (no material idling), and outputs the instructions for adding and the instructions for sucking the paper box. The pushing mechanism pushes the instructions and a tray of material into the open paper at the pushing station (the pushing has safety protection, and the jamming stops). After the paper box is closed, the finished product is output, and the unqualified products are removed.

Chinese

Chinese