客户案例

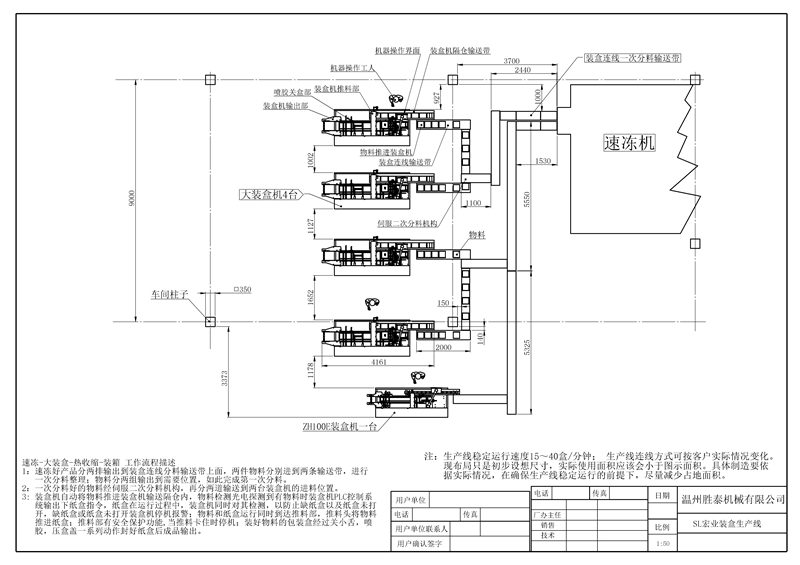

Work flow of quick-freezing machine - food cartoning machine - heat shrinkable packaging machine - packing machine

1. The quick-frozen food is output to the cartoning line feeding conveyor belt in two rows, and the two materials are fed into the two conveyor belts respectively for sorting at one time; The material is output to the required position in two groups, so as to complete the first material distribution.

2. The materials that have been separated at one time are conveyed to the feeding position of the two cartoning machines in two ways through the servo secondary distribution mechanism.

3. The cartoning machine automatically pushes the materials into the conveying compartment of the cartoning machine. When the photoelectric detection of the materials detects that there are materials, the PLC control system of the cartoning machine outputs the carton command. During the operation of the carton, the cartoning machine also detects the cartons to prevent the shortage of cartons and the carton is not opened, the shortage of cartons or the carton is not opened, the cartoning machine stops and alarms, and the materials and cartons arrive at the pushing department at the same time, and the pushing head pushes the materials into the carton; The pushing section has a safety protection function. When the pushing is stuck, the machine will stop. The packing box with materials will be sealed by a series of actions, such as small tongue, glue spraying, and box cover pressing, and then the finished product will be output.

Note: The production line runs at a steady speed of 15~40 boxes/minute, and the connection mode of the production line can be changed according to the actual situation of customers.

Chinese

Chinese