Four benefits of 3D transparent film packaging machine:

Four benefits of 3D transparent film packaging machine:

1. Good sealing effect against moisture/dust

2. It is easy to unpack, as long as the unpacking cable (easy cable) is pulled and turned for one week, it can be unpacked

3. Anti-counterfeit, which can be printed on the easy-to-pull line with signs such as pictures and words or trademarks to identify the authenticity

4. After packaging, it can hold a high product quality culture/improve the added value of the product/improve the grade and fill the quality.

Working performance requirements of this machine:

1. The continuous working time of the coating machine is 15 hours/day

2. The production capacity of the packaging machine is 20-30 bags/minute.

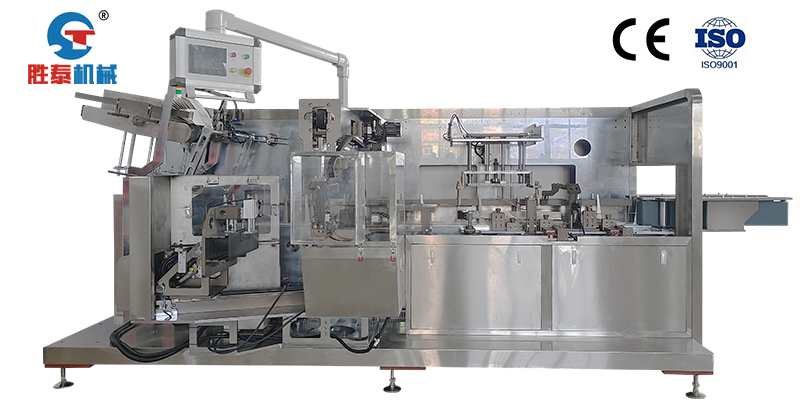

Main performance and structural features:

1. This machine takes mechanical linkage as the main body, applies the body-fitting wrapping principle, and adopts multi-function digital display variable frequency stepless speed regulation; PLC programmable control design technology to realize automatic control of heat sealing and shaping temperature, automatic feeding and automatic counting:2. When the servo motor is used for film falling, a stabilized pressure air pump is configured to assist in film falling to make the film falling stable and eliminate the interference of static electricity:

3. Key electrical components adopt Siemens brand to realize human-machine interface operation. It can complete programming, control operation, tracking and display, and automatic protection of card box overload, so the machine stops:

4. This machine has the function of completing the whole process of assembling, stacking, wrapping, welding, sealing, and body-fitting of single packaging box at one time (commonly known as medium packaging). The packaged drugs are beautiful, direct and marketable

5. The closed cover, shell, platform and parts in contact with drugs are made of high-quality sanitary non-toxic 304 stainless steel, which meets the GMP requirements for drug production

Four benefits of 3D transparent film packaging machine:

1. Good sealing effect against moisture/dust

2. It is easy to unpack, as long as the unpacking cable (easy cable) is pulled and turned for one week, it can be unpacked

3. Anti-counterfeit, which can be printed on the easy-to-pull line with signs such as pictures and words or trademarks to identify the authenticity

4. After packaging, it can hold a high product quality culture/improve the added value of the product/improve the grade and fill the quality.

Working performance requirements of this machine:

1. The continuous working time of the coating machine is 15 hours/day

2. The production capacity of the packaging machine is 20-30 bags/minute.

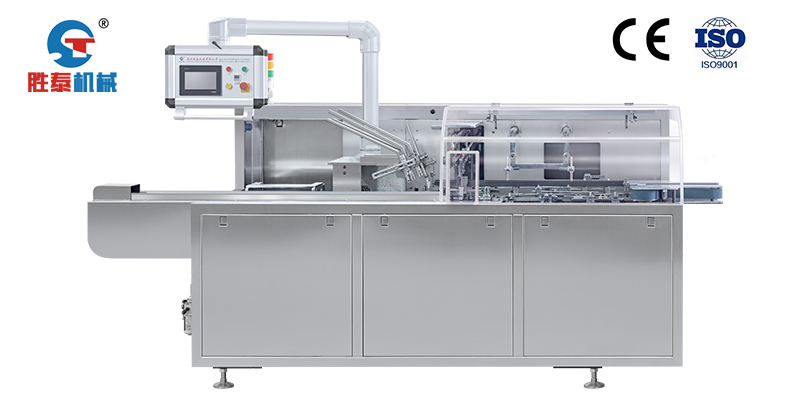

Main performance and structural features:

1. This machine takes mechanical linkage as the main body, applies the body-fitting wrapping principle, and adopts multi-function digital display variable frequency stepless speed regulation; PLC programmable control design technology to realize automatic control of heat sealing and shaping temperature, automatic feeding and automatic counting:2. When the servo motor is used for film falling, a stabilized pressure air pump is configured to assist in film falling to make the film falling stable and eliminate the interference of static electricity:

3. Key electrical components adopt Siemens brand to realize human-machine interface operation. It can complete programming, control operation, tracking and display, and automatic protection of card box overload, so the machine stops:

4. This machine has the function of completing the whole process of assembling, stacking, wrapping, welding, sealing, and body-fitting of single packaging box at one time (commonly known as medium packaging). The packaged drugs are beautiful, direct and marketable

5. The closed cover, shell, platform and parts in contact with drugs are made of high-quality sanitary non-toxic 304 stainless steel, which meets the GMP requirements for drug productionFour benefits of 3D transparent film packaging machine:

1. Good sealing effect against moisture/dust 2. It is easy to unpack, as long as the unpacking cable (easy cable) is pulled and turned for one week, it can be unpacked 3. Anti-counterfeit, which can be printed on the easy-to-pull line with signs such as pictures and words or trademarks to identify the authenticity4. After packaging, it can hold a high product quality culture/improve the added value of the product/improve the grade and fill the quality.

Working performance requirements of this machine:

1. The continuous working time of the coating machine is 15 hours/day 2. The production capacity of the packaging machine is 20-30 bags/minute.Main performance and structural features:

1. This machine takes mechanical linkage as the main body, applies the body-fitting wrapping principle, and adopts multi-function digital display variable frequency stepless speed regulation; PLC programmable control design technology to realize automatic control of heat sealing and shaping temperature, automatic feeding and automatic counting:2. When the servo motor is used for film falling, a stabilized pressure air pump is configured to assist in film falling to make the film falling stable and eliminate the interference of static electricity:

3. Key electrical components adopt Siemens brand to realize human-machine interface operation. It can complete programming, control operation, tracking and display, and automatic protection of card box overload, so the machine stops:

4. This machine has the function of completing the whole process of assembling, stacking, wrapping, welding, sealing, and body-fitting of single packaging box at one time (commonly known as medium packaging). The packaged drugs are beautiful, direct and marketable

5. The closed cover, shell, platform and parts in contact with drugs are made of high-quality sanitary non-toxic 304 stainless steel, which meets the GMP requirements for drug production

Chinese

Chinese