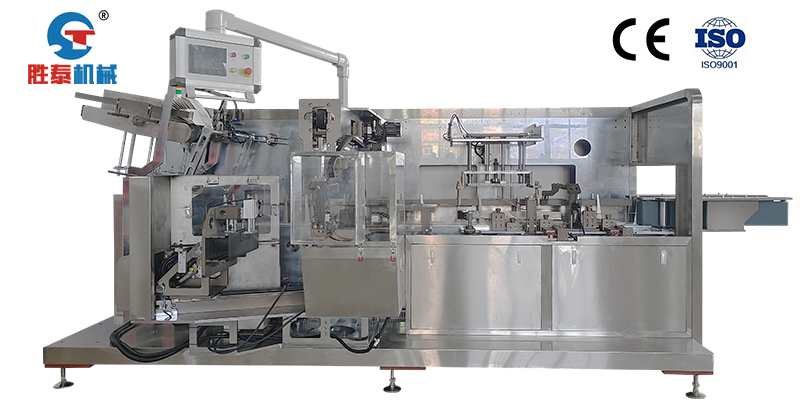

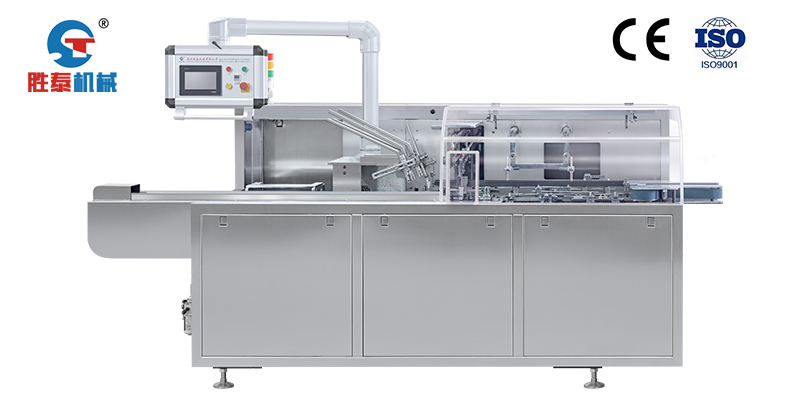

ST-260

Automatic Carton Packing Machine

Product Overview:The automatic cartoning machine for prefabricated vegetables mainly adopts the model STZ-260 machine. Large packaging specifications and wide range. It can be used to pack cooked food such as crayfish, pickled fish, boiled rice, takeaway fast food, covered rice and so on. The cartoning machine adopts a double suction box (upper and lower suction boxes) linkage structure. The size of the lower box is accurate and stable, greatly improving the failure rate of the lower box. This machine adopts domestic (foreign) well-known brand electrical components, and the performance of standard execution components is stable and reliable. (OMRON, Cisco, Schneider, ADK, etc.). With the functions of fault display, alarm and finished product counting, it is visual and convenient for regular maintenance and troubleshooting. Automatically kick out the finished packaging products that are lack of packaging materials or instructions to ensure the quality of the finished packaging products. It can automatically connect the front end to the bag packaging machine, and the back end to the heat shrinking packaging machine, coding machine, etc., with a high degree of automation.

Application industry

·Stationery packaging: pen, chalk, crayon, stapler, playing cards, ink paste, building blocks, etc.

·Pharmaceutical packaging: oral liquid, medicine bottle, vial, bagged granule, antipyretic patch, etc.

·Food packaging: ice cream, wafer roll, biscuits, chocolate, pastries, bagged coffee, tea bags, etc.

·Daily necessities packaging: toothpaste, cosmetics, perfume, facial mask, antipyretic patch, condoms, pregnancy test paper, mosquito-repellent incense, etc.

·Fragile items packaging: bearings, bulbs, switches, sockets, electric relay, chargers, etc.

·Auto parts packaging: spark plugs, filters, piston rings, automotive bulbs, automotive appliances, valves and so on.

·Tissue paper packaging: napkin, tampon, pads, cotton pads, etc.

Machine Performance and Parameters

|

Item/model |

ST-260 |

|

Paper quality of carton |

250-450g/m²(up to the size of package) |

|

Maximum packing specification |

L(90-260)mm×W(60-130)mm×H(30-90)mm(Special size can be customized) |

|

Packing speed |

30-80 cartons/minute

|

|

Motor power |

1.5 KW |

|

Power supply type |

3phase 4wire 380V 50HZ/60HZ |

|

Machine noise |

≤80dB |

|

Air supply |

0.5-0.8 Mpa |

|

Air consumption |

120-160L/min |

|

Machine Size |

L3800mm×W1350mm×H1900mm |

|

Machine weight |

1500Kg |

Main Components List

|

No. |

Components |

Model |

Brand |

|

1 |

PLC |

CPIE-N30DT-D |

Japan Omron |

|

2 |

PLC Extended Module |

CPIE-C1F11 |

Japan Omron |

|

3 |

Touch Screen |

NB7W-TWOOB |

Japan Omron |

|

4 |

Inverter |

3G3JZ-A4015 |

Japan Omron |

|

5 |

Photoelectric Sensor |

SICK 121 |

SICK |

|

6 |

Motor |

CH-1500-10S 1.5KW |

Taiwan CPG |

|

7 |

Index Drive |

0S83-4L-180 |

Zhejiang |

|

8 |

Encoder |

E6B2-XWZ6C 1000P/R |

Japan Omron |

|

9 |

Power Switch |

DRP024V120W1AA |

Taiwan Delta |

|

10 |

AC contactor |

LC1E3210M5N |

French Schneider |

|

11 |

Air Switch |

OSMC32N3C32 |

French Schneider |

|

12 |

Air Switch |

OSMC32N3C20 |

French Schneider |

|

13 |

Air Switch |

OSMC32N2C20 |

French Schneider |

|

14 |

Air Switch |

OSMC32N1C10 |

French Schneider |

|

15 |

Red Switch |

ZB2-BR4C |

French Schneider |

|

16 |

Red Bottom Switch |

ZB2BZ102C |

French Schneider |

|

17 |

Yellow Switch |

ZB2-BR5C |

French Schneider |

|

18 |

Green Bottom Switch |

ZB2BZ101C |

French Schneider |

|

19 |

Emergency Stop Switch |

ZB2-BS54C |

French Schneider |

|

20 |

Glue machine |

PROBLUE7 1022232 |

NordsonAmerica |

Chinese

Chinese