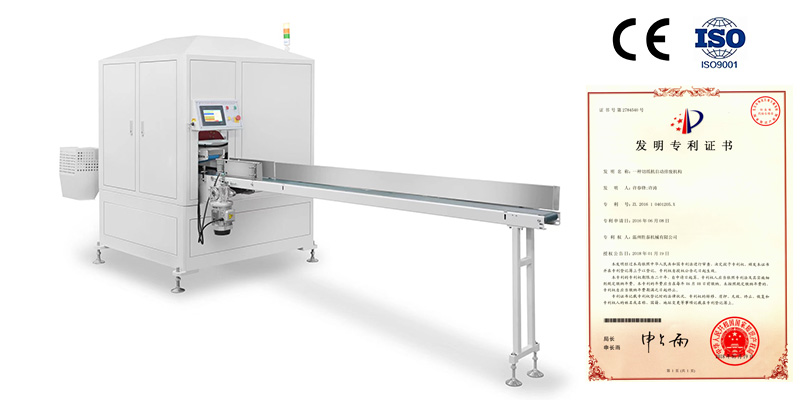

ST-200

Large rotary paper cutter

Product Overview:The working principle of the high-speed large rotary paper cutter is that the tissue paper produced by the paper extractor is put into the large rotary conveyor belt according to a certain amount. The conveyor belt delivers the tissue paper to the machine head. The upper and lower conveyor belts of the machine head clamp the tissue paper and transport it forward. The rotary knife cuts the paper into the required length, and then outputs it to the next mechanism for packaging.

Technical parameters of large rotary paper cutter:

|

Project model |

ST-200 (single channel) |

|

Raw material specification |

Width 45-110mm adjustable; The thickness is 60-120mm adjustable (other dimensions need to be customized) |

|

throughput |

60-200 cuts/min |

|

Cut length |

Free setting (within the adjustable range) |

|

Round knife size |

φ 610mm |

|

Power supply |

Three-phase four-wire 380V50HZ: 10KW |

|

Air source |

0.5-0.8Mpa |

|

Gas consumption source |

100-160L/min |

|

Overall dimension |

L2160 × W1380 × H1850MM |

|

Operating Weight |

1800kg |

Five innovations of large rotary paper cutter:

1. Automatic length averaging without accumulated error;

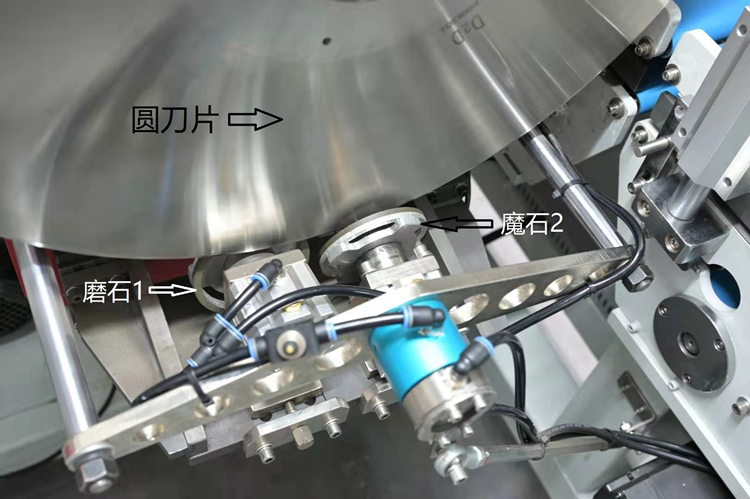

2. German sharpening technology ensures blade quality;

3. Linear guide rail lifting, easy operation and maintenance;

4. Dual frequency conversion new technology, saving electricity> 20%;

5. Automatic head and tail removal, one machine for dual use.

Main performance characteristics of large rotary paper drawing and cutting machine:

1. When the tissue paper is fed into the cutting device by the conveyor belt, it will be automatically clamped by the upper and lower conveyor belts and sent to the cutter for cutting, with a flat cut and high accuracy;

2. The machine is equipped with an advanced electrical detection system, a large diameter rotary cutter, which can automatically set the length of paper cutting, and accurate cutting can reach 200 times per minute;

3. The cutting device is optimized and equipped with automatic lubrication/grinding system. The grinding wheel can automatically grind the blade accurately according to the cutting times;

4. The machine adopts advanced servo drive system, cyclotron variable frequency speed regulation, PLC programming, time frequency of tool grinding and lubrication, cutting speed and cutting length are set on the computer control screen; Pushing, cutting and sharpening become more smooth and continuous, fully reflecting the advantages of the machine;

5. The machine can manually set two paper cutting modes: long cutting and measuring strip paper re-splitting, which are more accurate;

6. It can be designed according to the customer's requirements to cut off the unevenness of the head and tail and automatically remove the waste;

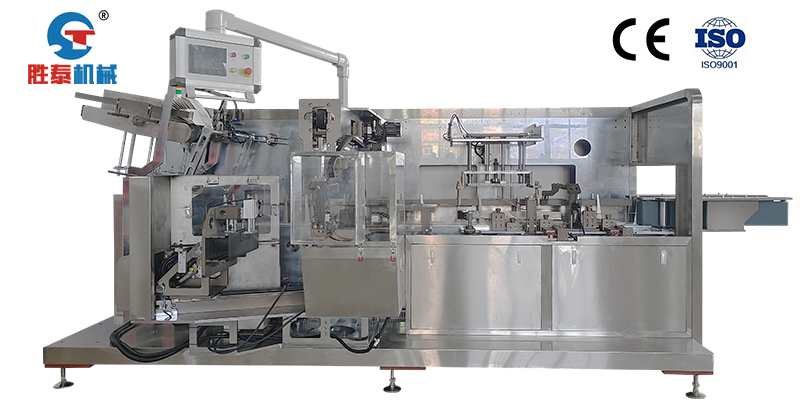

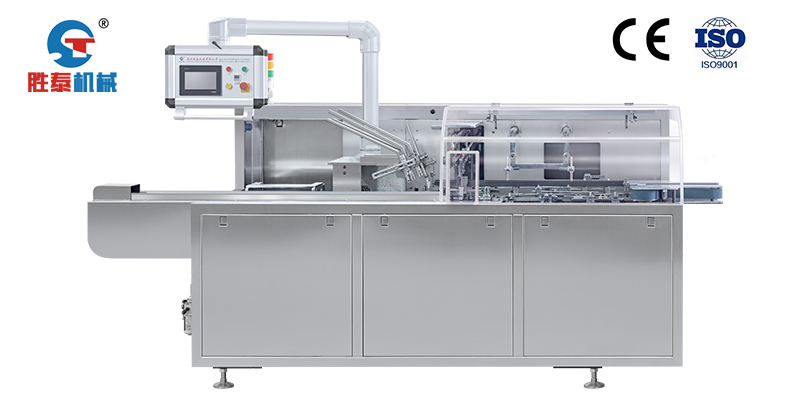

7. It can be connected with the paper extractor, automatic cartoning machine, soft paper extractor and other equipment for production.

Chinese

Chinese