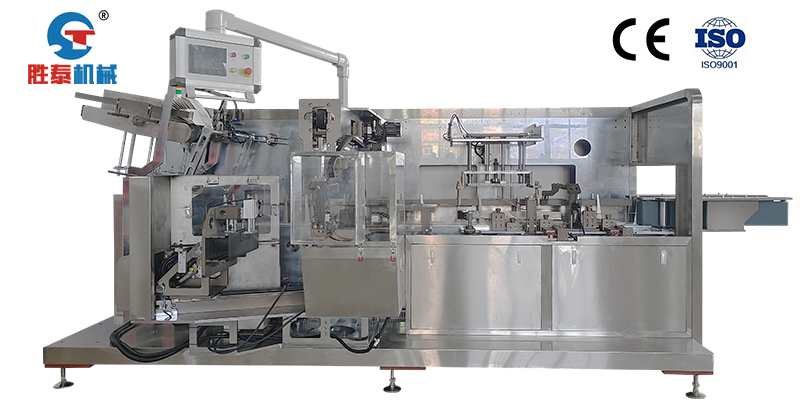

ST-120

Automatic box feeding and sealing machine

Product Overview:ST-120 cartoning machine is mainly a mechanical movement that uses the main motor output, the input sprocket, chain, belt pulley, connecting rod, gear, and the combination of servo motor, planetary reducer, cam splitter, sensor, encoder and other auxiliary functions to realize the function conversion, to achieve the product cartoning structure with stable operation, high efficiency, superior quality of processed products, easy and fast operation and many other advantages. It is suitable for automatic packaging of daily necessities, hardware accessories, etc.

Five innovations of this automatic cartoning machine:

1. High productivity, stable speed up to 100 boxes/minute;

2. Full function, half box/full box, paper high box low/paper low box high;

3. Fast production change, only 10-20 minutes to change specifications;

4. Easy to operate, servo paper feeding and PLC control system are easy to master;

5. The cost is low, and the amount of glue in the 0.3mm-0.36mm nozzle of imported glue machine is small;

Features of this automatic cartoning machine:

1) It adopts the packaging forms of automatic feeding, box opening, box entry, glue spraying, box sealing, waste removal, etc., with compact and reasonable structure and simple operation and adjustment;

2) Adopt servo/stepper motor, touch screen and PLC programmable control system, human-machine interface display operation is clear and simple, with high degree of automation and more humanization;

3) The photoelectric eye automatic detection and tracking system is adopted, which can save packaging materials to the maximum extent;

4) Large packaging range, convenient adjustment, and fast conversion between various specifications and sizes;

5) It is not necessary to replace all molds to change specifications, but only a small number of accessories and adjustments;

6) Adopt automatic stop and main drive motor overload protection device when the goods are not in place to ensure safe and reliable operation;

7) According to customer requirements, the up-turning safety cover can be used, which is easy to operate and beautiful in appearance.

8) It can realize linkage production with large rotary cutting machine, heat shrinkable film packaging machine, three-dimensional packaging machine and other equipment;

9) It can design various automatic blanking devices and cartoning systems according to the requirements of packaging materials;

10) According to the customer's requirements, hot-melt adhesive machine and hot printer can be selected.

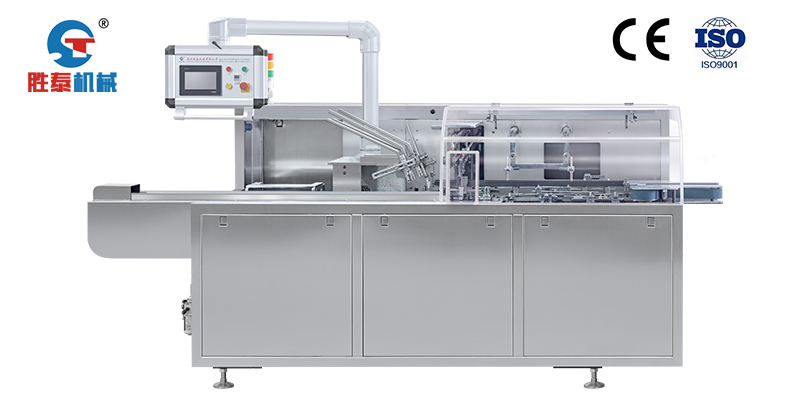

This automatic cartoning machine:

|

Item/model |

ST-100 |

|

Paper requirements |

300-400g/m3 |

|

Package specification |

L(100-240) × W(100-120) × H(20-90)mm |

|

Packaging speed |

30-80 boxes/min |

|

Power of hot melt adhesive machine |

2.32KW |

|

Motor power |

2.74KW |

|

Total power |

6.2KW |

|

Power supply type |

Three-phase five-wire 380V 50Hz |

|

Machine noise |

≤80dB |

|

Gas & nbsp;& nbsp; source |

0.5-0.8 Mpa |

|

Gas consumption |

120-160L/min |

|

Host size |

L3250 × W1650 × H1800mm |

|

Conveyor size |

L2000 × W260 × H1200mm |

|

Operating Weight |

2100kg |

Chinese

Chinese