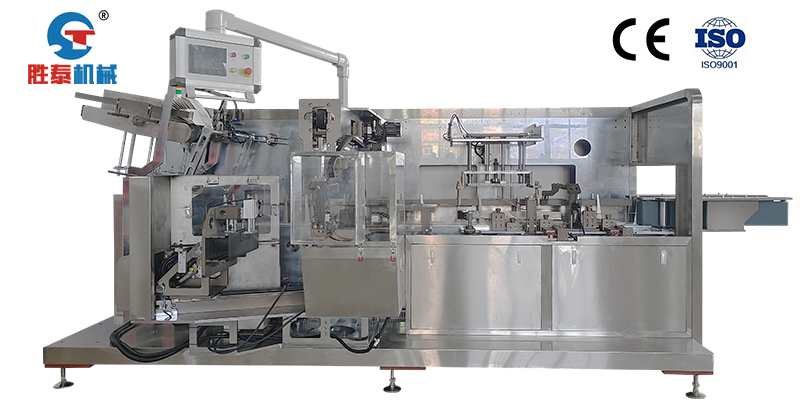

STZ-120

Multi-functional automatic cartoning machine

Product Overview:The multifunctional automatic cartoning machine uses a series of more precise mechanical transmission and the cooperation of optical fiber, electricity and gas to complete the processes of detection, feeding, material handling, box sending, box opening, box filling, inspection, box sealing, shaping, waste removal and finished product output. It is suitable for automatic packaging of pharmaceuticals, food, cosmetics, hardware, daily necessities, etc., with a wide range of uses.

Multi-functional automatic cartoning machineMain performance and structural features:

1. The machine adopts a double suction box (upper and lower suction boxes) linkage structure, which can make the material in place in one step, stable feeding, accurate sealing, and equipped with detection, scrap removal and other process stations. When the equipment is running, the transmission of various parts is light, stable, low noise and other advantages, greatly improving the life cycle of the equipment;

2. Adopt PLC and human-machine interface automatic control operation system, stepless frequency conversion speed regulation, high degree of automation, intelligent modular integration of display screen, easy to understand operation (including Chinese and English versions);

3. This machine adopts domestic (foreign) famous brand electrical components, standard executive components, etc., with stable and reliable performance. (Omron, Cisco, Schneider, Adecco, Nuxin, etc.);

4. Safety measures: the main machine adopts the mechanical overload automatic shutdown alarm function to ensure the safety of personnel using the machine;

5. Automatically remove the packaging products that lack the packaging materials or instructions to ensure the quality of the packaging products;

6. It has the functions of fault display, alarm and finished product counting, which is convenient for maintenance and troubleshooting;

7. In the process of mechanical parts, the material used is strictly controlled;

8. Optional hot melt adhesive machine adopts hot melt adhesive spray sealing or hot melt adhesive brushing device;

9. According to customer requirements, we can design various automatic feeders and conveying mechanisms;

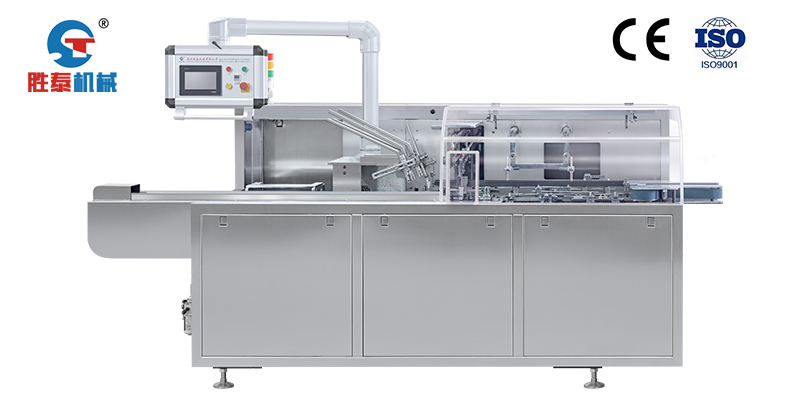

Full-automatic box sealing machineTechnical parameters:

|

model |

STZ-120 |

|

Paper requirements |

280-350g/m2 (depending on the size of the carton) |

|

Package specification |

L65-200mm × W35-120mm × H15-75mm (adjustable according to product specifications) |

|

Packaging speed |

30-100 boxes/min |

|

Main engine motor power |

2kw |

|

Total power |

2kw (actual deviation) |

|

Power supply type |

380V 50HZ/60HZ three-phase five-wire |

|

Machine noise |

≦80dB |

|

Air source |

0.5-0.8Mpa |

|

Gas consumption |

120-160L/min |

|

Overall dimensions of the machine |

4200mm × 1430mm × 1740mm |

|

Operating Weight |

2000kg |

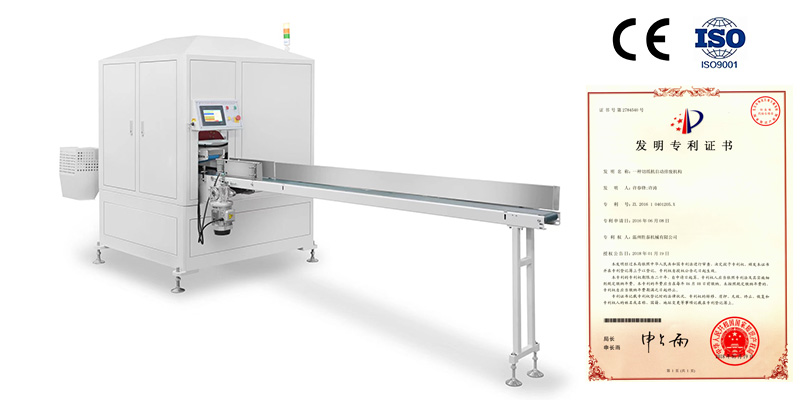

Multi-functional automatic cartoning machineWorking principle:

The cartoning machineis generally divided into three entrances: the entrance of instructions, the entrance of products and the entrance of cartons. The whole process from the feeding of the carton to the final packaging and molding can be roughly divided into four stages: the carton is fixed by a guide rail clamp and opened by a push plate. At the same time, two forward-moving clamps will rise from the bottom to clamp the side of the carton from the front and rear directions, so that the box opens at right angles and moves forward to the filling area. After filling in the filling area, the mechanism of the machine will fold the ears into the left and right guide rails, and then carry out the closing action. Before closing the cover, the mechanism will bend the tab of the carton first, and then a push plate will push the box cover to bend, so that the tab can be inserted into the box and the latch can be fastened. The closing action is a key action, and the quality of completion is closely related to the structure of the carton and the accuracy of machine adjustment.

About price:

Due to the different configurations, specifications and sizes of the equipment, the parameters and prices are for reference only. Please provide the information of the products to be packaged, and we will make a detailed quotation.

About delivery:

Due to different equipment, each equipment is customized according to customer needs, and the delivery date depends on the complexity of the equipment.

About after-sales:

① Installation and commissioning: After the equipment is delivered, our company will assign special personnel to install and debug the equipment and provide free technical training.

② Within the warranty period: the whole equipment is guaranteed free of charge for one year, with the exception of vulnerable parts, and the replacement and maintenance of spare parts are provided free of charge (excluding abnormal damage).

③ Beyond the warranty period: when the equipment is damaged, the buyer needs to pay for the replacement parts (priced according to the material purchase cost).

④ Maintenance commitment: In case of any failure during the use of the equipment, the power supply shall be cut off and our company shall be informed. We will submit the solution as soon as possible and notify the buyer.

Chinese

Chinese