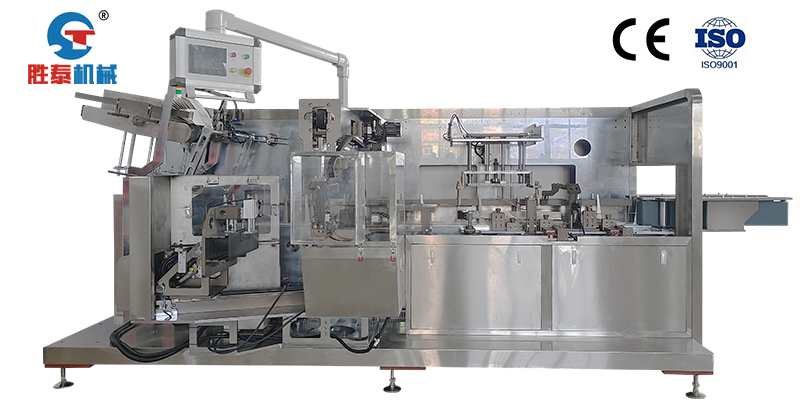

STZ-100

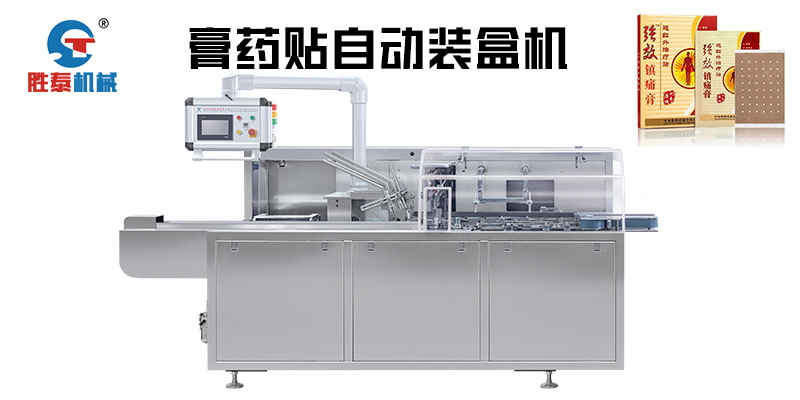

Full-automatic plaster pasting and boxing machine

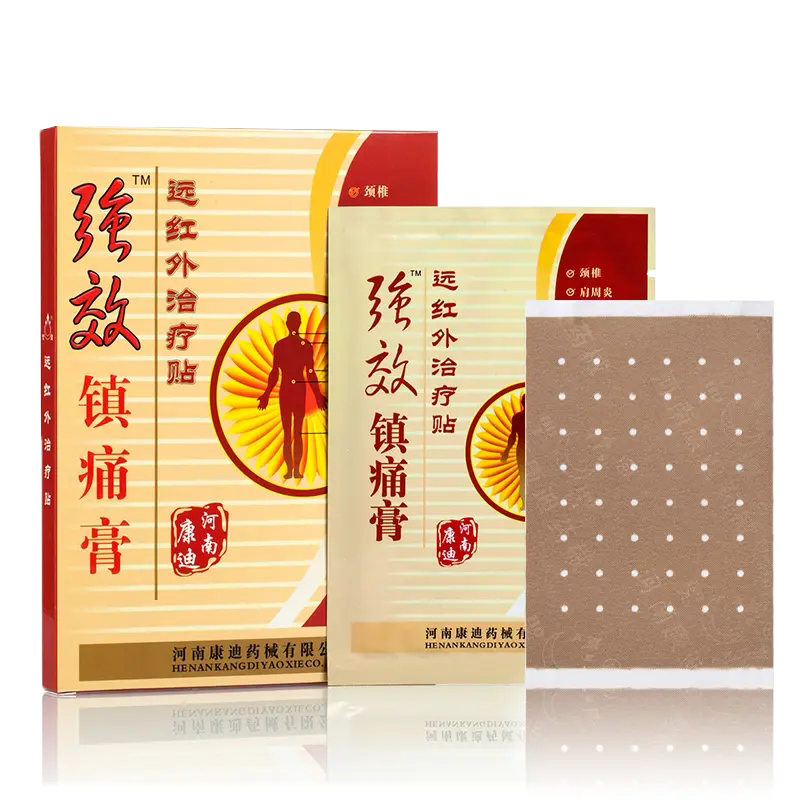

Product Overview:The fully automatic plaster pasting and cartoning machine is mainly used for packaging plaster products such as antipyretic patches, plaster patches, facial mask, masks, etc. The equipment can be connected to the four-sided sealing packaging machine or pillow packaging machine, and can also be equipped with automatic material handling machine to cut several pieces. The cartoning machine adopts tongue-type sealing and labeling.

The fully automatic plaster pasting and cartoning machine is mainly used for packaging plaster products such as antipyretic patches, plaster patches, facial mask, masks, etc. The equipment can be connected to the four-sided sealing packaging machine or pillow packaging machine, and can also be equipped with automatic material handling machine to cut several pieces. The cartoning machine adopts tongue-type sealing and labeling.

Technical parameters of the automatic paste pasting and boxing machine:

|

model |

STZ-100 |

|

Paper requirements |

280-350g/m2 (depending on the size of the carton) |

|

Package specification |

L65-200mm × W35-80mm × H15-75mm |

|

Packaging speed |

30-100 boxes/min |

|

Folding machine speed |

30-100 boxes/min |

|

Paper requirements of instructions |

55-65g/m2 |

|

Specification of instruction paper |

Max=260x190mm; min=100x100mm |

|

Main engine motor power |

1.5kw |

|

Total power |

2kw (actual deviation) |

|

Power supply type |

380V 50HZ/60HZ three-phase five-wire |

|

Machine noise |

≦80dB |

|

Air source |

0.5-0.8Mpa |

|

Gas consumption |

120-160L/min |

|

Equipment size |

L3026*W1182*H1769mm |

|

Operating Weight |

1800kg |

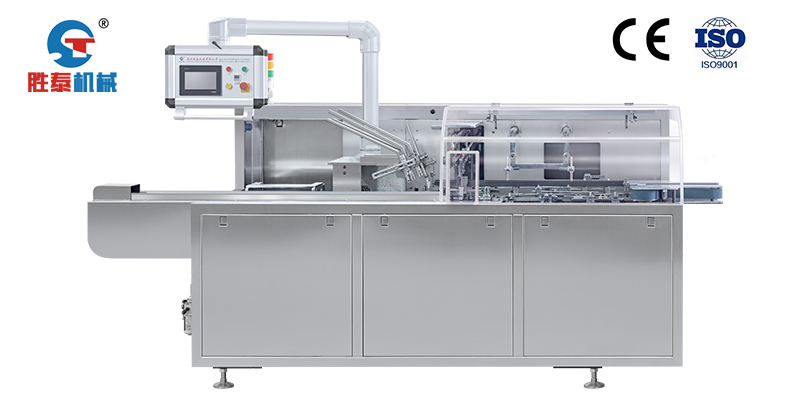

Main performance and structural features of the cartoning machine:

1. It adopts automatic opening (suction) box, folding instructions, blanking, feeding, batch number printing, box sealing, waste detection and other processes, with stable operation and low noise.

2. Adopt PLC and human-machine interface automatic control operation system, stepless frequency control, high degree of automation, easy to understand operation.

3. It adopts electrical components of international famous brands, with stable and reliable performance.

4. Adopt mechanical overload automatic shutdown function to ensure human-machine safety.

5. Automatically remove the packaging products that lack the packaging materials or instructions to ensure the quality of the packaging products.

6. It has the functions of fault display, alarm and finished product counting, which is convenient for maintenance and troubleshooting.

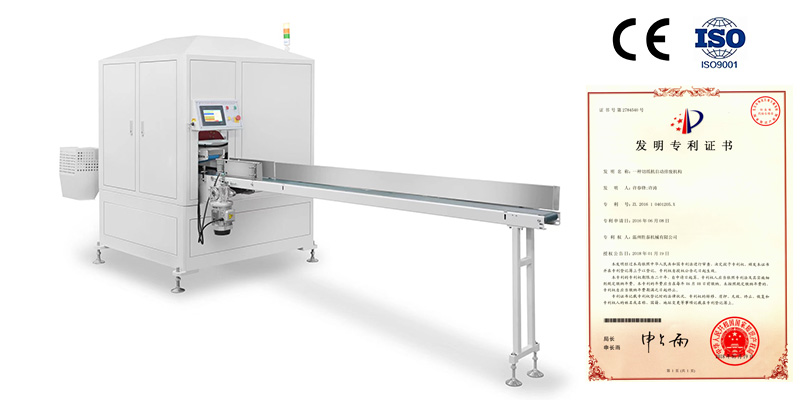

7. Various automatic feeders and conveying mechanisms can be designed according to customer requirements.

8. The hot melt adhesive machine can be equipped with hot melt adhesive spray sealing or hot melt adhesive brushing device.

9. It can realize joint and linkage production with aluminum plastic packaging machine, pillow packaging machine, filling machine, soap making machine, code spraying machine (or supervision code system), labeling machine, online weighing machine, three-dimensional packaging machine, heat shrinkable packaging machine, strapping machine, and other production lines.

Chinese

Chinese