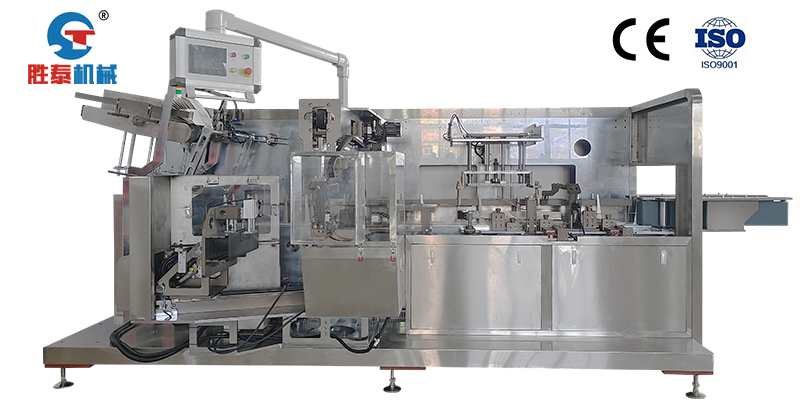

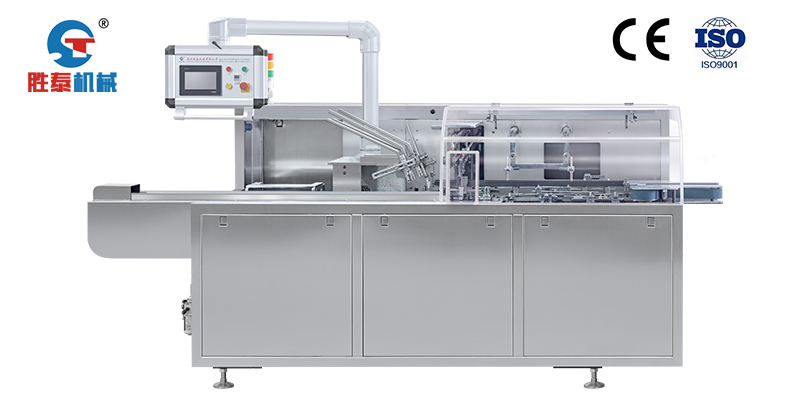

ST-80

Full-automatic paper extraction and sealing machine

Product Overview:The structure of the full-automatic paper extraction and sealing machine adopts a series of more precise mechanical transmission and the cooperation of optical fiber, electricity and gas to complete the processes of detection, feeding, material handling, box feeding, box opening, box loading, inspection, box sealing, shaping, waste removal and finished product output. It is suitable for automatic packaging of tissue paper, movable cutting paper, square tissue paper, handkerchief paper, cotton soft tissue, etc.

|

Item/model |

ST-80 automatic paper drawing and cartoning machine |

|

Paper requirements |

300-400g/m³ |

|

Package specification |

L(100-240) × W(100-120) × H(30-90)mm |

|

Packaging speed |

30-80 boxes/min |

|

Power of hot melt adhesive machine |

2KW |

|

Motor power |

2KW |

|

Total power |

4KW |

|

Power supply type |

Three-phase five-wire 380V 50Hz |

|

Machine noise |

≤80dB |

|

Gas & nbsp;& nbsp; source |

0.5-0.8 Mpa |

|

Gas consumption |

120-160L/min |

|

Host size |

L2874 × W1330 × H1600mm |

|

Conveyor size |

L900 × W383 × H1400mm |

|

Operating Weight |

1500kg |

When the material (tissue) is accurately pushed into the carton, the carton will continue to move forward under the drive of the carton chain. The carton is sealed by the closing tongue mechanism at the front end and the folding and sealing mechanism at the lower cover of the carton (at this time, the upper cover is open). When the paper box passes through the glue spraying delay photoelectric switch, the glue spraying mechanism will be instructed by the PLC to spray glue (no glue is sprayed without materials, the length and position of glue spraying can be set through the encoder screen on the touch screen, see the encoder setting instructions for details). After the glue spraying, the paper box will enter the box sealing station. After the paper box is sealed, it will be transported to the finished product output belt by the box feeding chain, and then output by the finished product output belt. An empty box removal device is installed on the finished product output belt to prevent the empty box from entering the next process

Four innovations of automatic paper extraction and sealing machine:

1. High productivity, stable speed up to 80 boxes/minute;

2. Full function, half box/full box, paper high box low/paper low box high;

3. Fast production change, only 10-20 minutes to change specifications;

4. Easy to operate, servo paper feeding and PLC control system are easy to master;

Product features:

1. The packaging form of automatic feeding, opening, filling, gluing, sealing, etc. of the cartoning machine is compact and reasonable in structure and simple in operation and adjustment

2. With the use of the servo motor, touch screen and PLC programmable control system, the human-computer interface display operation is clearer and simpler, with a high degree of automation and more humanization

3. The automatic material handling and conveying mechanism is convenient for linkage production with the automatic production line and can greatly reduce labor costs 4. The photoelectric eye automatic detection and tracking system is adopted to save packaging materials

5. Large packaging range, convenient adjustment, only 15 minutes to change specifications

6. It is not necessary to replace a large number of molds to change specifications, but only to adjust or replace individual parts

7. The automatic stop and main drive motor over-cut protection device are adopted when the goods are not in place, which is safer and more reliable

8. According to customer requirements, the up-turning safety cover can be used, which is easy to operate and beautiful in appearance.

Chinese

Chinese